Navy Shipyards: Actions Needed to Address the Main Factors Causing Maintenance Delays for Aircraft Carriers and Submarines

Fast Facts

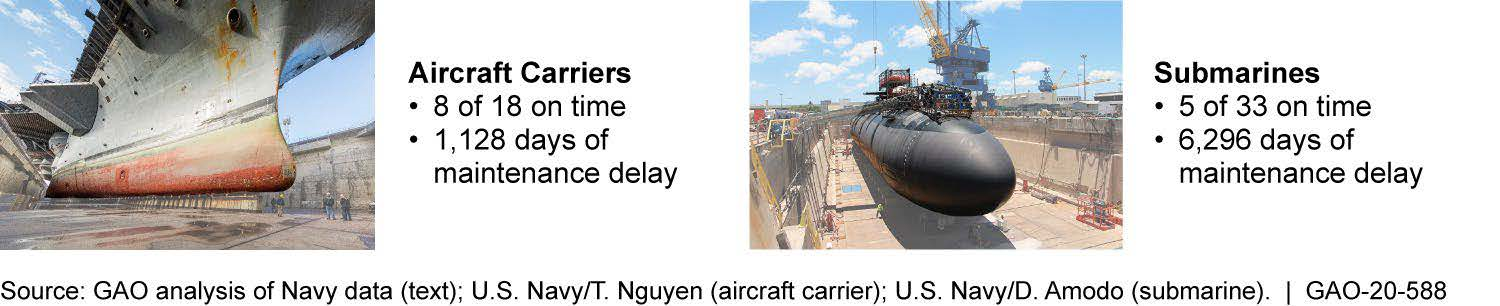

Substantial maintenance delays persist at the Navy's shipyards. 75% of planned maintenance periods were completed late for aircraft carriers and submarines in FY 2015-2019, with an average delay of 113 days for carriers and 225 days for submarines.

We identified 2 main causes for the delays:

Unplanned work, identified after maintenance planning is finished

Shipyard workforce performance and capacity

As a result, the Navy relies on excessive use of overtime. Our recommendations include addressing workforce requirements to avoid excessive overtime.

A Submarine Undergoing Maintenance at Pearl Harbor Naval Shipyard and Intermediate Maintenance Facility

Highlights

What GAO Found

The Navy's four shipyards completed 38 of 51 (75 percent) maintenance periods late for aircraft carriers and submarines with planned completion dates in fiscal years 2015 through 2019, for a combined total of 7,424 days of maintenance delay. For each maintenance period completed late, the shipyards averaged 113 days late for aircraft carriers and 225 days late for submarines.

Maintenance Delays at Navy Shipyards for Fiscal Years 2015 through 2019

Unplanned work and workforce factors—such as shipyard workforce performance and capacity (having enough people to perform the work)—were the main factors GAO identified as causing maintenance delays for aircraft carriers and submarines. The Navy frequently cited both factors as contributing to the same days of maintenance delay. Unplanned work—work identified after finalizing maintenance plans—contributed to more than 4,100 days of maintenance delays. Unplanned work also contributed to the Navy's 36 percent underestimation of the personnel resources necessary to perform maintenance. The workforce factor contributed to more than 4,000 days of maintenance delay on aircraft carriers and submarines during fiscal years 2015 through 2019.

The Navy has taken steps but has not fully addressed the unplanned work and workforce factors causing the most maintenance delays. First, the Navy updated planning documents to improve estimates and plans to annually update these data, but knowing whether changes improve results may take several years. Second, the Navy has consistently relied on high levels of overtime to carry out planned work. GAO's analysis found that high overtime among certain production shops, such as painting or welding, averaged from 25 to 32 percent for fiscal years 2015 through 2019, with peak overtime as high as 45 percent. Furthermore, shipyard officials told us that production shops at all four shipyards are working beyond their capacity. Overtime at such rates has been noted as resulting in diminished productivity. Third, the Navy initiated the Shipyard Performance to Plan initiative in the fall of 2018 to address the unplanned work and workforce factors, but it has not yet developed 13 of 25 planned metrics that could improve the Navy's understanding of the causes of maintenance delays. In addition, the Shipyard Performance to Plan initiative does not include goals, milestones, and a monitoring process along with fully developed metrics to address unplanned work and workforce weaknesses. Without fully developing metrics and implementing goals, action plans, milestones, and a monitoring process, the shipyards are not likely to address unplanned work and workforce weaknesses and the Navy is likely to continue facing maintenance delays and reduced time for training and operations with its aircraft carriers and submarines.

Why GAO Did This Study

For fiscal years 2015 through 2019, the Navy spent $2.8 billion in capital investments to address shipyard performance, among other things. However, the shipyards continue to face persistent and substantial maintenance delays that hinder the readiness of aircraft carriers and submarines.

The Senate Armed Services Committee, in a report accompanying a bill for the National Defense Authorization Act for Fiscal Year 2019, included a provision for GAO to review Navy shipyards' performance. GAO evaluated the extent to which the Navy (1) completed maintenance at its shipyards on time on aircraft carriers and submarines in fiscal years 2015 through 2019, (2) has identified the main factors leading to maintenance delays, and (3) has addressed the main factors affecting any delays in that maintenance. GAO reviewed data related to Navy shipyard maintenance for fiscal years 2015 through 2019, analyzed factors contributing to delays and plans to address them, visited all four Navy shipyards, and met with Navy and shipyard officials.

Recommendations

GAO is making three recommendations to the Navy, including updating workforce planning requirements to avoid the consistent use of overtime; completing the development of shipyard performance metrics; and developing and implementing goals, action plans, milestones, and monitoring results. The Navy concurred with all three recommendations.

Recommendations for Executive Action

| Agency Affected | Recommendation | Status |

|---|---|---|

| Department of the Navy |

Priority Rec.

The Secretary of the Navy should ensure that the Naval Sea Systems Command fully analyzes the use of overtime among shipyard production shops, and updates workforce requirements to avoid the consistent use of overtime to meet planned maintenance requirements. (Recommendation 1) |

The Navy concurred with this recommendation and took action to reduce the amount of workload being completed at the shipyards, which in turn reduced the excessive use of overtime. Specifically, through a study conducted by the Center for Naval Analysis in December 2022, the Navy fully analyzed its use of overtime among the shipyards. It determined that there was an 18 percent variance in workload requirements and shipyard capacity, but the ideal variance should be 3 percent. In turn, the Navy updated its workforce requirements and has used the Program Objective Memorandum 24 to reduce the workload variance down to around 7 percent, and it has planned for the Program Objective Memorandum 25 to reduce the workload variance down to around 3 percent. This decrease in workload variance has shown improvements in the amount of overtime used between fiscal years 2021 and 2023, with additional improvements projected into fiscal year 2024. By taking this action, the Navy has addressed our recommendation and is better prepared to meet planned maintenance requirements.

|

| Department of the Navy | The Secretary of the Navy should ensure that the Naval Sea Systems Command identify a timeframe for completing the development of metrics for its Shipyard Performance to Plan initiative and complete the development of metrics to address the main factors contributing to maintenance delays and improve the timely completion of ship maintenance at Navy shipyards. (Recommendation 2) |

The Navy concurred with this recommendation and took action to develop the planned metrics that could improve the Navy's understanding of the causes of maintenance delays. Specifically, in July 2022, Navy officials told us they further developed the original 25 metrics and expanded them to 33 metrics. According to the documentation provided, the Navy identified internal organizations responsible for developing each metric, available data, and how the metrics fed into each other. By developing metrics for measuring the factors affecting the performance of maintenance at the Navy's four shipyards, the Navy may be able to better address the ongoing delays in ship maintenance.

|

| Department of the Navy |

Priority Rec.

The Secretary of the Navy should ensure that the Naval Sea Systems Command develop and implements goals, action plans, milestones, and a monitoring process for its Shipyard Performance to Plan initiative to address the main factors contributing to maintenance delays and improving the timely completion of ship maintenance at Navy shipyards. (Recommendation 3) |

The Navy concurred with our recommendation. Naval Sea Systems Command stated in December 2020 that to address this recommendation, the command had developed metrics for the identified drivers of maintenance delays and was working to identify levers that it can use to facilitate improvements. As of February 2023, the Navy developed goals, milestones, and monitoring for the top-tier performance metrics it has identified. As of April 2024, the Navy had established a baseline for its metrics based on the previous two years and established goals for the next 12 months. Further, these goals are to be adjusted to reflect expected gains from directed improvement efforts, what the Navy refers to as "interventions." Finally, the Naval Sea Systems Command implemented a digital dashboard to communicate data analysis results to project teams for tactical use and to senior Navy leadership for strategic planning and decision making. By taking these actions, the Navy has addressed our recommendation and could increase the overall availability of aircraft carriers and submarines to perform needed training and operations in support of their various missions.

|