Military Depots: Army and Marine Corps Need to Improve Efforts to Address Challenges in Measuring Performance and Planning Maintenance Work

Fast Facts

The Army and Marine Corps operate large industrial depots to maintain, overhaul, and upgrade weapon systems and equipment. Delays at depots reduce the available time for operations and training with tanks, radars, and other weapons and equipment.

Both services reported largely meeting depot maintenance goals in recent years. We found ways they could improve depot performance measures and efficiency. The Army, for example, could do more to better plan the flow of work to depots.

We made 4 recommendations to the Army and 1 to the Marine Corps, including ways to more comprehensively assess depot performance and address weaknesses.

A tracked vehicle is worked on at the Anniston Army Depot

Military vehicle

Highlights

What GAO Found

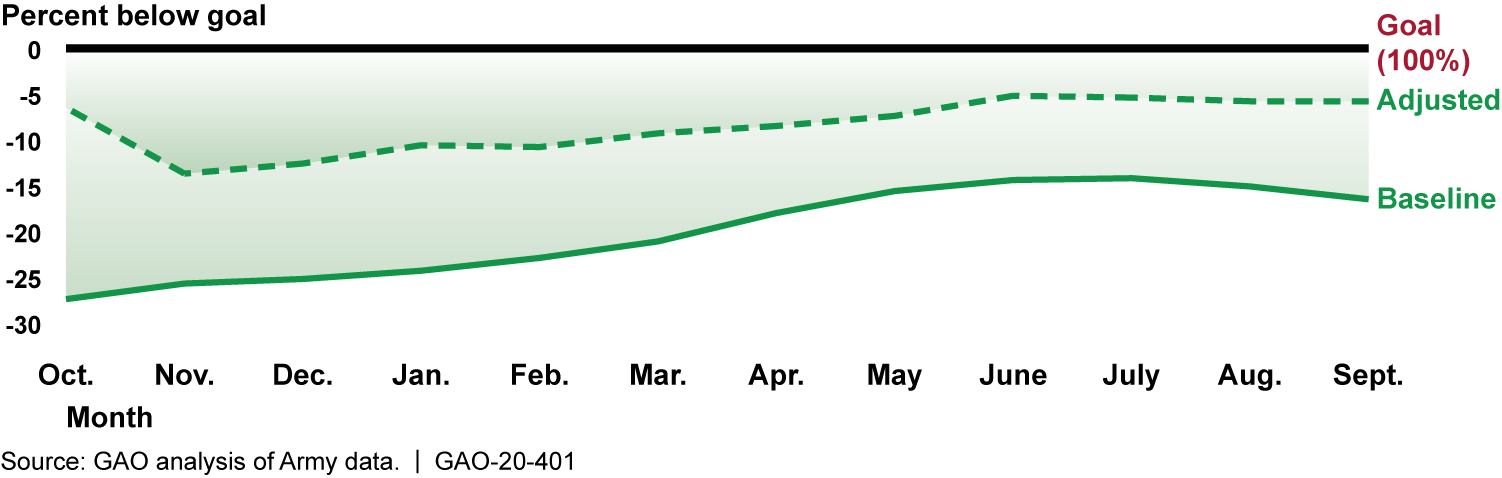

The Army reported that it met its goals for about 91 percent of the systems on which it planned to complete maintenance for its customers in fiscal years 2018 and 2019, but its key performance metric has some limitations. Recognizing these limitations, Army Materiel Command (AMC), which oversees the Army depots, has begun assessing performance against monthly (adjusted) and annual (baseline) goals (see figure). AMC also began an effort to improve its performance metrics, but depot officials involved in the effort whom GAO interviewed are uncertain how AMC will incorporate their input. Without AMC procedures to ensure that it will incorporate depot input, as called for by Army guidance on effective teamwork, AMC cannot be assured that it is developing metrics that are beneficial at all levels for assessing depot performance.

Percent Variance from Goal for Average Adjusted and Baselined Depot Performance across Army Depots for Fiscal Year 2019

The Army identified a key challenge to meeting the depots' maintenance goals in fiscal years 2018 and 2019, but it has not fully addressed this challenge. During this time the Army experienced schedule changes to more than half of its planned maintenance work. GAO found that most of this variability was caused by changing customer needs and identified two key shortcomings in the Army's approach to minimizing such changes. First, the Army does not have guidance establishing time frames for depot customers to submit their needs during depot planning, resulting in millions of dollars in unplanned work. Without such guidance, depots will continue to experience workload variability. Second, AMC has not systematically analyzed why depot customers have changes, resulting in incomplete information about causes and potential solutions. Without such analysis, the Army will be poorly positioned to address longstanding maintenance challenges.

For fiscal years 2015 through 2019, the Marine Corps reported generally meeting its yearly depot maintenance goals, but GAO found that the Marine Corps has not yet included all its planned work in its baseline schedule for a key performance metric. The Marine Corps also experienced monthly variability in fiscal year 2019 for a variety of reasons, including parts shortages, lack of asset availability, and changing customer needs, and it is undertaking several initiatives to minimize such changes. However, developing a complete baseline will allow the Marine Corps to better assess its performance against its planned maintenance work and better identify and mitigate the causes and effects of any unfavorable performance.

Why GAO Did This Study

The Army and Marine Corps operate large industrial depots to maintain, overhaul, and upgrade numerous weapon systems and equipment. The depots play a key role in sustaining readiness by completing maintenance on time and returning refurbished equipment to warfighting customers.

The Senate Armed Services Committee, in a report accompanying a bill for the National Defense Authorization Act for Fiscal Year 2019, included a provision for GAO to review Army and Marine Corps depots. GAO evaluated the extent to which (1) the Army met its planned maintenance goals and addressed any challenges in measuring depot performance; (2) the Army identified and addressed any key challenges in completing planned maintenance; and (3) the Marine Corps completed its planned maintenance and addressed associated challenges. GAO reviewed depot planning processes; analyzed maintenance goals and data for fiscal years 2018 and 2019 for the Army and fiscal years 2015 through 2019 for the Marine Corps; and met with Army and Marine Corps headquarters, command, and depot officials.

Recommendations

GAO is making five recommendations, including that the Army develop procedures to ensure depot input on metrics, develop guidance for depot customers, and analyze the causes of maintenance changes; and that the Marine Corps develop a complete baseline. DOD concurred with all five recommendations.

Recommendations for Executive Action

| Agency Affected | Recommendation | Status |

|---|---|---|

| Department of the Army | The Secretary of the Army should ensure that the Commander, Army Materiel Command, develops procedures to help ensure that it will incorporate depot stakeholder input into the new metrics framework for the Army's organic industrial base through iterative and ongoing processes. (Recommendation 1) |

The Army concurred with this recommendation, stating that Army Materiel Command (AMC) is committed to continuing its collaboration with the Life Cycle Management Commands (LCMCs), Depots, Arsenals, and Ammunition plants as it refines its performance metrics. In April 2022, the Army stated that AMC has implemented 42 of 97 Strategic, Operational, and Tactical level measures and metrics that it developed with stakeholder support. The officials stated that the Army convenes both weekly interactive user sessions, and quarterly stakeholder reviews involving: life cycle management commands, depots, AMC Staff Sections, and the supporting Contractor to address user issues and track progress for these corrective actions. For example, based on the official AMC meeting minutes that the Army provided to us, stakeholders from 4 life cycle management commands routinely attended weekly updates during February and March 2022. Based on these actions, we are closing this recommendation as implemented.

|

| United States Marine Corps | The Commandant of the Marine Corps should ensure that the Marine Corps Logistics Command establishes a complete baseline schedule, which includes all planned depot maintenance work for the fiscal year, against which to measure performance. (Recommendation 2) |

The Marine Corps concurred with this recommendation and has taken several actions to implement it by better identifying depot-level reparable requirements and other customer requirements for inclusion in the budget prior to the year of execution. First, according to documentation we reviewed, the Marine Corps began adding depot-level reparables to its baseline master schedule for fiscal year 2020, and by fiscal year 2023 had added all depot-level reparables to its baseline master schedule for that year. Second, according to documentation we reviewed, the Marine Corps has developed a process for obtaining other customer requirements, which have also been included in the fiscal year 2023 baseline master schedule. This process includes setting a March 31st deadline for its other customers to provide key information about their requirements, so that the Marine Corps can account for these requirements earlier as it prepares its baseline schedule for the following fiscal year. According to documents provided, any other workload that comes after March 31st will require additional approval to ensure that the Marine Corps depots have the capability and capacity to meet that workload. By taking these steps to identify and include depot-level reparable and other customer requirements into its baseline master schedule (which documentation shows has continued in the fiscal year 2024 schedule), the Marine Corps has met the intent of this recommendation.

|

| Department of the Army | The Secretary of the Army should ensure that the Commander, Army Materiel Command, develops guidance that synchronizes the Army's timelines for required inputs from Army depot maintenance customers who use funds from the Procurement; Research, Development, Test, and Evaluation; and Operations and Maintenance budgets with the depots' timelines for development of their finalized budget estimate submissions to AMC. (Recommendation 3) |

The Army concurred with this recommendation, stating that Army Materiel Command is establishing an "Improved Organic Industrial Base (OIB) Workloading Review Process" to synchronize plans with all Lifecycle Management Commands, OIB installations, OIB customers (including Inter-service and other government/non-government agencies), and supply chain partners (including DLA). In response to our recommendation, the Commanding General, AMC, held a detailed review to plan for fiscal 2022 workload in October 2020, and again in September 2021. The Army stated that the AMC commander first initiated these reviews in April and June 2020, before our report was issued. According to Army documentation, these reviews identified gaps and opportunities to improve workload planning data and the overall execution of customer workload, including work funded by Army Procurement; Research, Development, Test, and Evaluation; and Operations and Maintenance accounts . For example, the June 2020 review addressed gaps in the procurement-funded workload planning process. and helped to synchronize workload planning with the process for developing the depots' budget estimates. We were unable to determine whether the Army realized any specific financial saving as a result of these efforts. However, we are closing this recommendation as implemented, based on the actions taken to date.

|

| Department of the Army | The Secretary of the Army should ensure that the Commander, Army Materiel Command, provides its non-Army customers with guidance that will help ensure that the depots have all updated maintenance needs in sufficient detail from non-Army customers prior to the depots' finalized budget estimate submissions to AMC. (Recommendation 4) |

The Army concurred with this recommendation, stating that that Army Materiel Command's (AMC) recently established "Improved Organic Industrial Base (OIB) Workloading Review Process" will ensure that the Army has the detailed information on maintenance needs from non-Army customers that is required to finalize budget estimates. We have confirmed by reviewing Army documentation that non-Army customers were invited to at least two AMC "deep dives" of depot workload planning, including one in June 2020 (before our report was published) and also in September 2021. Additionally, in May 2022, according to Army documentation, the Army concurred with a draft DOD-wide instruction, which will provide all stakeholders an additional four to six months to provide the Army with workload planning data, in support of the Army's budget estimate submission. Our review of the draft instruction indicates that the Army would be able to use the Instruction to specify when non-Army customers would need to provide their workload requirements to the Army on a case-by-case basis. According to the Department of Defense (DOD) official responsible for drafting the instruction, the instruction should be issued in fiscal year 2023. Based on these actions, we believe the Army has met the intent of our recommendation and we are closing it as implemented.

|

| Department of the Army | The Secretary of the Army should ensure that the Army Organic Industrial Base Corporate Board oversees a study that includes a recurring, comprehensive, and systematic analysis of Army depot data to identify trends and causes behind changes in depot maintenance schedules; and that it uses this analysis to recommend actions to reduce unplanned maintenance work, as appropriate and necessary. (Recommendation 5) |

The Army concurred with this recommendation. In response, the Army's Organic Industrial Base Corporate Board (OIBCB) had initiated a comprehensive review of depot metrics and governance actions. According to OIBCB documentation, the board reviews quarterly trends of several metrics, including trends in new orders and carryover, that may cause the depot to change their schedules. The OIBCB then can make recommendations to address these causes. For example, according to an OIBCB briefing, as of April 2022 the board's Carryover and Metrics Integrated Process Team has recommended workload acceptance policy and regulation changes, and that the Army establish and report against specific goals. Based on actions taken to date we are closing this recommendation as implemented.

|