Science & Tech Spotlight: Critical Minerals from Seawater

Highlights

Why This Matters

Important technologies, including electric vehicle batteries, smartphones, and solar panels, require “critical” minerals such as magnesium and lithium. But the U.S. obtains most of these minerals from foreign countries, including some adversaries. Wars, trade embargoes, or other supply disruptions could seriously affect U.S. manufacturing, energy production, the defense industrial base, and other industries. Developing domestic sources could help mitigate these risks.

Key Takeaways

- Technology advances make it possible to extract critical minerals from the brine left over from desalinating seawater.

- While researchers have successfully extracted minerals from seawater desalination brine, scalability and economic viability have not been demonstrated yet.

- Policymakers and industry face questions such as which minerals to extract and how to compare this source to other options, such as terrestrial mining and importation.

The Technology

What is it? Seawater contains many dissolved minerals, including several that the U.S. government has identified as critical for national security and for economic sectors such as renewable energy and infrastructure. Although the concentration of minerals in seawater is low, the volume of water in the oceans potentially offers vast quantities of minerals for extraction.

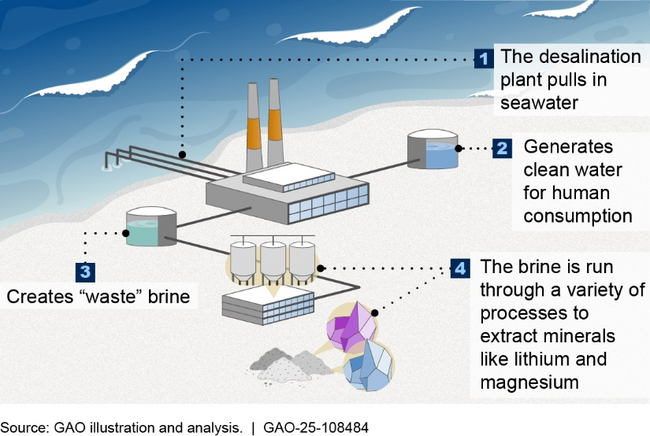

One promising option is to extract minerals from the waste created by seawater desalination plants. These facilities remove salt and other minerals from seawater, producing fresh water to bolster municipal supplies. The process also produces brine that is traditionally considered a waste product, but has two times the mineral concentration of seawater. Researchers have successfully extracted critical minerals from this brine, demonstrating that it could be an option to reduce U.S. dependence on foreign sources.

How does it work? Critical minerals found in seawater desalination brine include magnesium, lithium, and gallium, which can be extracted using several different techniques. For example, one way to extract lithium is through an electrically driven separation process that uses a membrane filter. The filter enables lithium ions in the brine to pass through, while blocking other ions. The collected material is further refined to produce minerals of a quality to be processed into industry-ready material for rechargeable batteries and other products.

Figure 1: Extracting Minerals from Desalination Brine

How mature is it? Pilot programs are underway in multiple countries, and one early project has begun full-scale operations. Specifically, the Saudi Water Authority (SWA) in Saudi Arabia reports that it has launched a facility that concentrates magnesium from seawater desalination brine. However, its output is not for industrial use but for supplementing drinking water to prevent magnesium deficiency. SWA continues to study filtration and extraction technologies to produce minerals for industrial use. Pilot programs, such as a 2-year pilot underway at Oregon State University, aim to demonstrate scalability and economic viability. Universities and private industry continue to research technologies to recover more minerals from desalination brine and to extract multiple minerals at once.

Opportunities

- Meet increasing demand. Demand for critical minerals is rising, in part because of growing demand for electronics such as electric vehicle batteries and computers.

- Reduce foreign dependence. A domestic source of critical minerals could help alleviate international supply concerns.

Challenges

- Few seawater desalination plants. As of 2018, only about a dozen desalination plants in the U.S. use seawater, which could limit the supply of mineral-rich brine.

- Lack of mineral processing infrastructure. Minerals need to be processed after extraction from desalination brine to make them usable by industry. But the U.S. has few processing facilities, and transporting raw minerals for processing abroad could increase costs and lead to new supply chain vulnerabilities.

- Legal requirements. U.S.-based critical mineral extraction projects and associated infrastructure may be subject to various federal and state legal requirements, depending on project parameters.

- Uncertain economics. The economic viability of extracting minerals from desalination brine depends significantly on the amount of brine processed. It is unclear whether the costs of extraction technologies can be justified because of variations in technology costs and mineral market values.

Policy Context and Questions

- How can extraction from seawater be part of the overall strategy to ensure an adequate U.S. supply of critical minerals?

- How can the U.S. ensure that future brine extraction efforts focus on minerals that are increasing in demand or prone to international supply disruptions?

- To what extent are existing U.S. desalination plants located in areas suitable for constructing extraction and processing facilities?

- What information could help assess the economic, environmental, and social trade-offs of obtaining critical minerals from seawater desalination brine?

Selected GAO Work

Critical Minerals: Status, Challenges, and Policy Options for Recovery from Nontraditional Sources, GAO-24-106395.

Critical Materials: Action Needed to Implement Requirements That Reduce Supply Chain Risks, GAO-24-107176.

Selected References

Department of Energy, Office of Energy and Renewable Energy, Powering the Blue Economy: Exploring Opportunities for Marine Renewable Energy in Maritime Markets (Washington, D.C. 2019). https://www.energy.gov/sites/prod/files/2019/03/f61/73355.pdf

Sharkh, B.A., Al-Amoudi, A.A., Farooque, M. et al. Seawater desalination concentrate—a new frontier for sustainable mining of valuable minerals. npj Clean Water 5, 9 (2022).

For more information, contact Karen L. Howard, PhD at howardk@gao.gov.