Manufacturing Extension Partnership: Centers Cite Benefits from Funding Change, but Impacts Hard to Distinguish from Other Factors

Fast Facts

Commerce's Manufacturing Extension Partnership (MEP) Program has centers in each state that help small- and medium-sized companies improve their technology and management practices.

Recent legislation set the cost sharing ratio at 1:1, reducing the cost burden for some centers. All centers now match federal funding dollar for dollar. Prior to the change, the cost share increased over time from $1 for $1 to $2 for each $1.

Most centers told us this change improved their financial stability, allowing them to better serve very small and rural companies; however, recent program changes and other factors make it hard to determine the exact impact.

A computer-aided cutting tool at a small cabinet manufacturer that has used services provided by the Manufacturing Extension Partnership program to help cut costs

A machine and nearby worker in a cabinet manufacturing facility

Highlights

What GAO Found

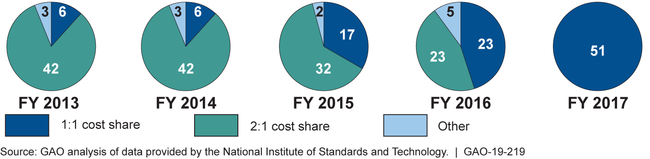

Most Manufacturing Extension Partnership (MEP) centers reported that the January 2017 American Innovation and Competitiveness Act (AICA) cost share adjustment has helped them serve manufacturers, especially very small (i.e., less than 20 employees) and rural ones. The AICA adjusted the cost share ratio to remain at 1:1, that is, $1 of nonfederal contributions for each $1 of federal assistance. Before the adjustment, MEP centers' cost share requirement increased over the course of their cooperative agreements from 1:1 to 2:1, requiring centers to obtain a greater proportion of revenue from nonfederal sources. In GAO's survey of all 51 MEP centers, 44 centers cited positive effects of the adjustment on center operations, such as helping to improve center services or better reach underserved manufacturers. Also, 41 centers indicated the adjustment increased their financial stability, which some centers stated has allowed them to focus less on revenue generation and to serve very small and rural manufacturers. However, some MEP center officials observed that the AICA cost share adjustment impact is hard to distinguish from other factors, such as the National Institute of Standards and Technology's (NIST) recompetition of nearly all centers' cooperative agreements between fiscal years 2014 and 2017. The recompetition increased the level of federal financial assistance for most centers and reset many centers' cost share ratio from 2:1 to 1:1 prior to the 2017 adjustment. Still, center officials said that if the cost share requirement reverted to what it was prior to the 2017 adjustment, centers would be less able to serve manufacturers, particularly very small and rural ones.

Number of Manufacturing Extension Partnership Centers Operating Under Various Cost Share Ratios, Fiscal Years (FY) 2013 through 2017

NIST data show that there have been some changes in MEP centers' finances and activities since the AICA cost share adjustment; however, these changes generally began prior to the adjustment. For example, NIST data on centers' finances show an increase in federal assistance and a decrease in reported nonfederal contributions from fiscal year 2017 to 2018, but these changes generally began around fiscal year 2014, when NIST began the recompetition process. Similarly, NIST data on centers' activities show an overall increase in the numbers of very small and rural manufacturers served from fiscal year 2017 to 2018. While the change in the number of very small manufacturers served began around fiscal year 2014, the number of rural manufacturers served fluctuated from fiscal years 2014 through 2018. Like MEP center officials, NIST officials said the impact of the AICA cost share adjustment is intertwined with the recompetition impacts and, going forward, the AICA adjustment may help sustain recent increases in the number of very small and rural manufacturers served.

Why GAO Did This Study

Small and medium-sized manufacturers are an important part of the U.S. economy. In 1988, to enhance the competitiveness, productivity, and technological performance of U.S. manufacturing, NIST established what is now called the MEP program. The program supports manufacturers through services provided by MEP centers. The centers, located in all 50 states and Puerto Rico, are operated by nonfederal organizations. The MEP centers provide assistance, either directly or through third parties, to help improve manufacturing firms' processes and productivity; expand their capacity; and help them adopt new technologies, utilize best management practices, and accelerate company growth. NIST enters into a cooperative agreement with the nonfederal organization that runs each center to provide federal financial assistance conditional upon the center contributing nonfederal matching funds—known as a cost share.

The AICA included a provision for GAO to review the effect of the 2017 cost share adjustment. This report describes (1) the MEP centers' views regarding the extent to which the recent cost share adjustment has helped them serve manufacturers and (2) the extent to which NIST data show impacts of the cost share adjustment on centers' finances and activities. GAO surveyed all 51 MEP centers, analyzed NIST data on the MEP program, and interviewed NIST and MEP center officials.

For more information, contact John Neumann at (202) 512-3841 or neumannj@gao.gov.